How Automatic Packing Systems Transform Factory Productivity

In today's highly competitive manufacturing environment, speed and efficiency determine who leads the market. Factories across industries face the same challenge: how to increase output, reduce costs, and maintain quality, all at the same time. Manual packaging and semi-automated solutions can no longer keep up with the demands of modern supply chains.

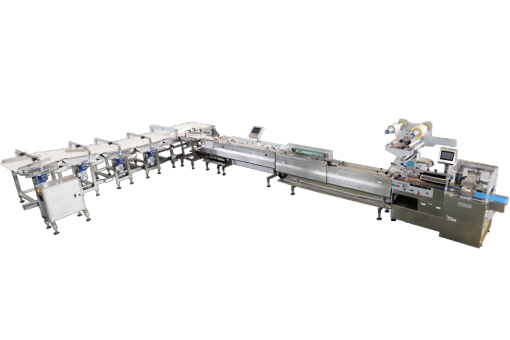

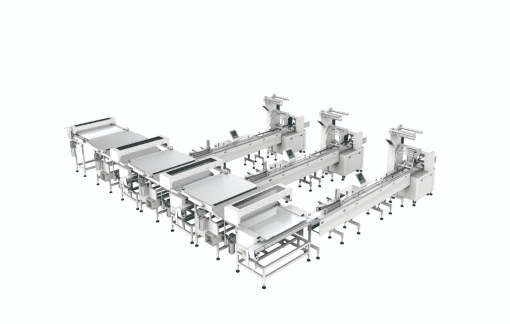

This is where automatic packing systems step in. More than just machines, they represent a comprehensive solution that transforms the entire packaging process. By integrating multiple packaging stages into one streamlined system, automatic packing systems dramatically improve factory productivity and future-proof manufacturing operations.

What Is an Automatic Packing System?

An automatic packing system is an integrated packaging line that combines:

- Product sorting and feeding – Aligning products for consistent packaging.

- Primary packaging – Wrapping or sealing products using flow wrap machines, vertical packing machines, or pillow pack machines.

- Secondary packaging – Placing products into cartons, boxes, or bundles using carton machines.

- Tertiary packaging – Preparing products for storage or transport (e.g., case packing, shrink wrapping, or palletizing).

Instead of managing these processes separately, an automatic packing system connects them into one synchronized flow. Products move from production to final packaged form without unnecessary delays or manual handling.

How Automatic Packing Systems Improve Factory Productivity

1. Boosting Speed and Output Capacity

Manual packaging often limits factories to a few dozen units per minute. In contrast, automatic packing systems can handle hundreds—or even thousands—of units per hour, depending on configuration. This level of speed allows manufacturers to:

- Meet peak season demand without temporary labor.

- Scale operations without physically expanding factory space.

- Reduce downtime between product runs.

For example, a snack manufacturer using a Soontrue flow wrap and carton packing line can increase packaging speed while ensuring every product is sealed perfectly.

2. Ensuring Packaging Accuracy and Quality

Packaging is not just about covering a product—it's about protecting it and presenting it correctly. Automatic systems guarantee:

- Accurate filling for powders, liquids, or granules.

- Consistent sealing and wrapping, minimizing defects.

- Proper labeling and coding, critical for traceability.

For industries like food, beverage, and pharmaceuticals, where safety standards are strict, this level of accuracy ensures compliance and builds consumer trust.

3. Reducing Labor Costs and Risks

Hiring and training packaging staff is becoming increasingly difficult and costly. With automation:

- Fewer workers are needed for repetitive manual tasks.

- Labor can be reallocated to higher-value roles, such as quality control and machine supervision.

- Worker safety improves by reducing exposure to repetitive motion and sharp tools.

In many cases, factories recover their investment in automatic systems within a few years due to lower labor costs and higher efficiency.

4. Offering Flexibility for Different Products

One common concern among buyers is whether an automated system can handle multiple product types. Modern systems, like those from Soontrue, are designed with flexibility in mind.

- Food manufacturers can switch between snacks, noodles, and baked goods with minimal changeover.

- Household product producers can run powder detergents, liquids, and wipes on the same line with modular add-ons.

- Frozen food companies can manage both bagged items and carton packaging on integrated systems.

This versatility makes automatic packing systems especially valuable for factories with a wide SKU range.

5. Minimizing Waste and Supporting Sustainability

Material waste adds hidden costs to packaging. Automatic systems help by:

- Cutting packaging film precisely, reducing excess use.

- Using intelligent filling controls to avoid product spillage.

- Supporting eco-friendly materials without compromising sealing quality.

For companies aiming to meet sustainability goals, adopting automation reduces both costs and environmental footprint.

6. Seamless Integration with Existing Production Lines

Automation only delivers value when it connects smoothly with upstream and downstream processes. Modern automatic packing systems feature:

- PLC-based controls for centralized management.

- Data connectivity (IoT-ready) for real-time monitoring.

- Compatibility with existing conveyors, labeling, and logistics systems.

This integration ensures continuous flow, reduces bottlenecks, and provides managers with insights to optimize operations.

Industries That Benefit the Most

Automatic packing systems deliver value across multiple industries:

- Food & Beverage – Biscuits, instant noodles, chocolate, frozen foods, sauces, dairy products.

- Pharmaceutical & Healthcare – Tablets, syrups, syringes, bandages.

- Personal Care & Cosmetics – Lotions, shampoos, facial masks.

- Household Products – Detergents, cleaning wipes, small hardware items.

Each industry benefits differently: food manufacturers value speed, pharmaceuticals require precision, and personal care brands emphasize consistent packaging aesthetics.

What Buyers Should Look for in an Automatic Packing System

Before investing, buyers should consider:

- Production Volume – Does the system meet current and future demand?

- Product Compatibility – Can it handle powders, liquids, solids, or fragile items?

- Packaging Flexibility – Does it support bags, cartons, or mixed formats?

- Ease of Use – How simple are cleaning, maintenance, and product changeovers?

- Integration Capabilities – Can it connect with ERP systems, printers, and logistics?

- After-Sales Service – Reliable support and spare parts availability are critical for long-term performance.

Why Choose Soontrue Automatic Packing Systems?

Soontrue is a trusted global manufacturer specializing in flow wrap machines, carton machines, vertical packing machines, and fully integrated automatic packing systems.

Factories choose Soontrue because:

- Tailored Solutions – Each system is customized for specific products, whether it's noodles, snacks, frozen foods, or non-food goods.

- Proven Performance – Soontrue machines are used worldwide by leading manufacturers to increase productivity while lowering costs.

- Integration Expertise – From single machines to complete lines, Soontrue ensures smooth connectivity across packaging stages.

- Global After-Sales Support – With service teams and technical expertise, Soontrue helps clients maintain consistent performance long after installation.

Learn more about Soontrue's automatic packing systems.

Conclusion

Automatic packing systems are not just about replacing manual labor—they represent a fundamental transformation in how factories operate. By adopting automation, manufacturers achieve:

- Faster packaging speeds and higher throughput.

- Consistent product quality and compliance.

- Lower operational costs and reduced waste.

- Flexibility to adapt to multiple product types.

- A future-ready production line capable of scaling with demand.

For factories aiming to stay competitive in today's fast-moving market, automatic packing systems are no longer optional—they are essential.

And with proven expertise in packaging automation, Soontrue provides the advanced technology, customization, and support that factories need to achieve maximum productivity.