How Automatic Shrimp Deheading Lines Improve Yield and Reduce Labor Costs

In the global seafood industry, efficiency and cost-control have become key competitive factors. Processing shrimp for export or retail requires high volumes, consistent quality, and tight control over labor costs. One of the critical steps in shrimp processing is head removal—traditionally a labor-intensive process prone to variation in yield and meat loss.

Enter the automatic shrimp deheading processing line, a solution designed to remove shrimp heads in a continuous, mechanised workflow, improving product yield and significantly reducing labour requirements. In this article we'll explore how these automated lines deliver value, what features contribute to improved yield and labour cost reduction, and how processors can evaluate and implement such systems successfully.

The Challenge with Manual Shrimp Deheading

Manual deheading of shrimp involves a large number of workers, each performing physically repetitive work, such as aligning shrimp, cutting or separating heads, and disposing of waste. This method has several drawbacks:

Labour cost: a high number of operators, shifts, supervision.

Inconsistent results: meat loss, variable quality, high defect rates.

Throughput limitations: manual speed and fatigue reduce output.

Hygiene and waste challenges: manual handling increases risk of contamination or inconsistent waste separation.

Studies of shrimp processing lines show that automation of processing steps—such as deheading—can result in increased output, better yield and reduced labour requirements.

How Automatic Deheading Lines Improve Yield

Here are the key ways in which an automated shrimp deheading line enhances yield:

Precise Head Separation with Minimal Meat Loss

Automated lines use engineered mechanisms—precision blades, conveyors, aligners—to sever shrimp heads at exactly the joint, avoiding unnecessary removal of flesh.

Consistent Results Across Size and Batch

Automated systems are often adjustable for shrimp of varying sizes and species.

Reduced Damage and Rejects

Mechanical conveyance and alignment reduce the risk of improper cuts, torn shells, or crushed bodies. Lower damage means fewer defects, less product loss, and higher overall yield.

Increased Throughput = More Product Processed

Because the automatic line can process more shrimp per hour than manual labour, the same input raw material yields a greater output of processed heads-removed shrimp.

How Automation Reduces Labour Costs

Beyond the yield benefits, the labour cost reduction is one of the most compelling reasons to adopt automatic shrimp deheading lines:

Fewer Operators Required

Where manual lines might require dozens of workers to stand, align, cut, sort, clean, and move shrimp, an automatic line may require only a small team—for example one operator feeding machines, one supervisor.

Lower Skill Requirement

Automated systems often require less manual dexterity or skill, so labour can be less specialised, fewer mistakes are made, and training time is shorter. This reduces ongoing labour overhead and variability.

Reduced Labour Fatigue and Turnover

Repetitive manual work leads to fatigue, errors, injury risk, and turnover. Automation improves worker safety, reduces errors, and lowers associated costs (training replacements, lost time). The technology of deheading machines is documented to improve safety and productivity.

Shift Productivity & Utilisation

Automatic lines can run longer, with fewer breaks, higher consistency, and better use of fixed-cost assets. This increases effective labour productivity (output per worker) and reduces cost per kg processed.

Additional Benefits Supporting Yield & Cost

While yield and labour cost are primary, automatic deheading lines offer several supporting benefits:

Improved Hygiene and Food Safety

Automated lines are typically designed with stainless-steel, wash-down capability, conveyors and sealed cutting zones. Hygiene improvements lead to fewer recalls, fewer food-safety incidents, and thus lower indirect costs.

Better Waste Handling and By-Product Recovery

Automated lines often separate heads, shells, and body parts in flows designed to capture by-products for disposal or conversion (e.g., shrimp heads for processing). This can provide secondary revenue or reduce waste disposal costs.

Scalability and Flexibility

As production demands scale up (seasonal peaks, export markets), automatic lines scale more easily than manual labour. The ability to handle variable shrimp sizes and species means less downtime or rework, supporting better yield and cost control.

Traceability & Quality Control

Modern lines may include sensors or monitoring (even if not full IoT) to detect misfeeds, jams, or errors. This means fewer errors, less product waste, improved overall yield and lower cost through less rework.

Key Considerations Before Investing

To maximise yield and labour cost reduction, processors should evaluate the following when selecting an automatic shrimp deheading processing line:

Capacity & Throughput: Ensure the line matches your volume requirements (kg/hour, pieces per minute).

Shrimp Size/Species Flexibility: The line should handle your shrimp size range with minimal settings change.

Yield Performance & Meat Loss Rates: Look for data on meat loss, damage rates, yield improvement.

Labour Requirement & Skill Level: Understand the operator count required and training needs.

Hygiene & Cleaning: Easy cleaning and maintenance reduce downtime and cost.

Integration with other processing steps: Whether it can integrate upstream (sorting) or downstream (peeling, freezing).

Return on Investment (ROI): Consider savings in labour, improved yield, reduced waste, increased throughput to calculate pay-back period.

Support & Maintenance: Spare parts, service, warranties matter for uptime and cost control.

Case Snapshot: Soontrue's Automatic Shrimp Deheading Processing Line

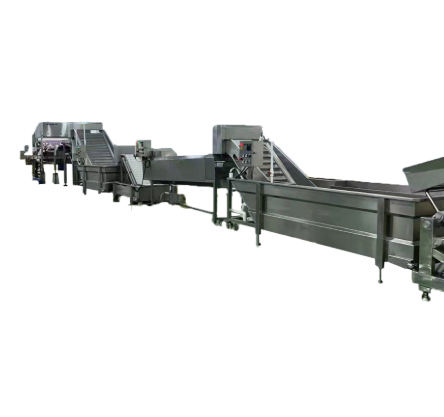

Soontrue offers an automatic shrimp deheading processing line (for example, model SDL100A) designed to support shrimp processors seeking improved yield and reduced labour costs. According to the product details:

- It automates deheading, washing, sorting and collecting device sequences.

- The manufacturer claims labour cost savings of up to 70%, throughput of approx 1000 kg/hour for certain size shrimp, and meat-loss/damage rates below 2%.

- The design supports alignment, head removal, wash-elevating and sorting in one continuous line, improving yield consistency and labour efficiency.

Processors evaluating automatic deheading lines may consider contacting Soontrue to discuss capacity, shrimp size range, yield improvement data, and labour savings tailored to their facility.

Conclusion

In today's shrimp processing industry, achieving high yield and controlling labour cost are critical to competitiveness. An automatic shrimp deheading processing line addresses both by delivering consistent, high-volume, precision head removal, reducing the dependency on manual labour and decreasing product loss.

Key benefits include:

- Increased yield due to minimal meat loss and consistent output

- Significant labour cost reduction through fewer operators, less training, improved productivity

- Supporting improvements via hygiene, waste handling, scalability and integration

When selecting such a line, processors should carefully review throughput, yield performance, labour requirement, hygiene design, integration potential and ROI. Companies like Soontrue are positioned to supply such lines, with documented success in global seafood plants.

By investing in the right automatic deheading line, shrimp processors can dramatically improve their operational efficiency, product quality and cost-structure—leading to stronger margins and better market positioning.