Top Benefits of Using Robotic Packing Machines in Food Industries

The food industry is constantly evolving, driven by the need for higher efficiency, improved quality, and enhanced safety standards. One of the most transformative technologies reshaping this sector is the robotic packing machine. These machines automate the packaging process, delivering consistent results while addressing many challenges faced by traditional manual packing methods. Below, we explore the major benefits of adopting robotic packing machines in food industries, highlighting how they contribute to operational excellence and competitive advantage.

Increased Efficiency and Productivity

Robotic packing machines significantly enhance production efficiency by automating repetitive and time-consuming tasks. Unlike human labor, robots can operate continuously without breaks, fatigue, or loss of focus, enabling food manufacturers to maintain steady output levels throughout the day. This continuous operation helps meet the increasing demand for packaged food products in a timely manner.

Moreover, robotic systems can handle complex packing sequences with speed and precision, reducing bottlenecks in production lines. Their ability to quickly switch between different packaging formats and products without extensive downtime further boosts productivity. This flexibility is especially valuable for food companies that offer a diverse range of products and need to adapt packaging lines rapidly to changing market needs.

Superior Accuracy and Consistency

One of the most critical aspects of food packaging is maintaining consistent quality to protect product integrity and ensure consumer satisfaction. Robotic packing machines excel in delivering uniform packaging by precisely handling each item with minimal variation. This consistency reduces the risk of packaging defects such as incorrect filling, improper sealing, or mislabeling.

Robots equipped with advanced vision systems can identify and orient products accurately, even when items are randomly placed on conveyors. This capability minimizes product damage and waste, which are common issues in manual packing processes. Consistent packaging quality also supports regulatory compliance and enhances brand reputation by ensuring that every package meets established standards.

Enhanced Workplace Safety

Food packaging often involves repetitive motions, heavy lifting, and exposure to potentially hazardous environments. By automating these tasks, robotic packing machines reduce the risk of workplace injuries such as strains, cuts, and repetitive stress disorders. This shift not only improves employee well-being but also lowers costs related to workplace accidents and absenteeism.

Furthermore, automation limits human contact with food products, which is crucial for maintaining hygiene and preventing contamination. In industries where food safety is paramount, robotic packing machines help uphold stringent sanitary standards by minimizing human intervention during the packaging process.

Flexibility and Adaptability

Modern robotic packing machines are designed to be highly adaptable to various packaging requirements. They can handle different product sizes, shapes, and packaging materials with ease, making them suitable for a wide range of food products—from delicate pastries to frozen goods. This adaptability allows manufacturers to respond quickly to new product launches or seasonal variations without the need for extensive equipment changes.

Advanced robotic systems also feature programmable gripping and handling techniques, enabling them to pack fragile items gently or handle heavier products securely. Such versatility ensures that packaging lines remain efficient and effective regardless of product diversity.

Cost Savings and Long-Term Value

While the initial investment in robotic packing machines can be considerable, the long-term financial benefits are substantial. Automation reduces labor costs by decreasing the reliance on manual packers and associated expenses such as training, turnover, and benefits. Additionally, robots minimize material waste by ensuring precise filling and sealing, which translates into savings on packaging supplies.

The durability and reliability of robotic systems also contribute to lower maintenance and downtime costs. Over time, these savings accumulate, providing a strong return on investment. Moreover, the increased throughput and improved product quality enabled by robots can open new market opportunities and enhance profitability.

Support for Sustainability Goals

Sustainability has become a key focus in the food industry, with companies seeking ways to reduce waste and energy consumption. Robotic packing machines contribute to these goals by optimizing packaging material usage and improving process efficiency. Precise control over packaging reduces excess material use, which helps lower environmental impact.

Automation also enables more efficient energy management on production lines, as robots operate with consistent power consumption and reduce the need for rework caused by packaging errors. These factors support companies’ commitments to sustainable manufacturing practices and appeal to environmentally conscious consumers.

Scalability and Traceability

Robotic packing solutions offer excellent scalability, allowing food manufacturers to increase production capacity by adding more robotic units without major infrastructure changes. This scalability is essential for businesses aiming to grow or respond to fluctuating demand.

In addition, many robotic packing systems integrate with digital tracking technologies, providing detailed traceability of packaged products. This capability enhances quality control and regulatory compliance by enabling manufacturers to monitor packaging processes, track batches, and quickly respond to any issues.

Discover Soontrue's Advanced Robotic Packing Solutions: Elevate Your Food Packaging Efficiency

For food manufacturers seeking to harness the full potential of robotic packing technology, Soontrue offers a comprehensive range of high-quality, innovative packaging machinery tailored to diverse industry needs. With over 30 years of experience and multiple manufacturing bases across China, Soontrue is a trusted leader in delivering efficient, reliable, and customizable packaging solutions.

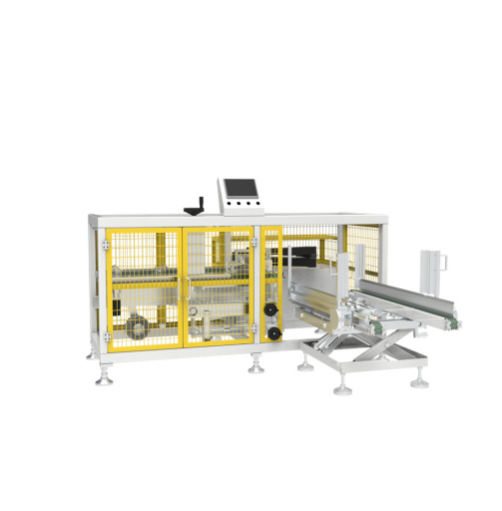

Our product portfolio includes advanced robotic case packers, flow packaging machines, vertical packaging machines, and fully integrated automated packaging lines. These machines are designed to seamlessly handle delicate food items, frozen products, snacks, and more, ensuring minimal product damage and maximum packing precision.

Whether upgrading existing lines or building new ones, our packaging solutions empower businesses to meet evolving consumer demands with confidence and efficiency.

Conclusion

Robotic packing machines are revolutionizing the food industry by delivering substantial benefits across efficiency, quality, safety, and cost management. The flexibility of modern robotic systems allows food manufacturers to adapt quickly to changing product lines and market trends.

Moreover, if you are looking for a reliable packing machine supplier, look no further than Soontrue! We offer a wide range of packaging solutions to fit different applications! Choose our packing machines and experience their differences today!