Box Erector Machine vs Manual Case Forming: Which Is Better for Your Business?

In modern packaging operations, efficiency, speed, and consistency determine whether a business can stay competitive. As order volumes increase—especially in industries such as e-commerce, food processing, pharmaceuticals, and logistics—many companies find themselves evaluating whether they should continue using manual case forming or switch to an automated box erector machine (also known as a box erecting machine or automatic case erector).

This article provides a comprehensive comparison between box erecting machines and manual box erection, helping you understand which option delivers the best return on investment for your packaging line. We will also explore productivity, labor cost, accuracy, safety, output stability, long-term maintenance, and integration into automated packaging lines.

What Is Manual Case Forming?

Manual case forming is the traditional method of forming cardboard cartons by hand. Workers take flat corrugated sheets, open them, fold the bottom flaps, and seal them with tape—usually with a handheld tape gun or stationary taping tool.

For small operations, this method may seem simple and convenient. However, manual forming quickly becomes inefficient as volume grows. Common problems include:

- Slower output speed

- Inconsistent box forming

- Increased labor costs

- Higher risk of injury due to repetitive motions

- Human error causing misalignment or weak seals

- Fatigue-related productivity drops

While manual forming may work for small warehouses, it is not ideal for medium to large-scale packaging lines where tens of thousands of cartons need to be produced every day.

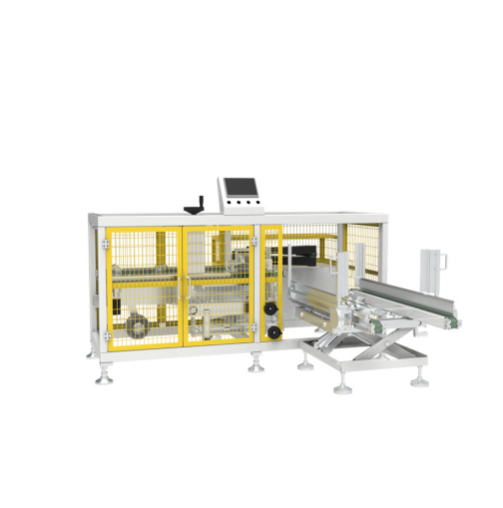

What Is a Box Erector Machine?

A box erector machine—or box erecting machine—automatically forms flat corrugated cartons into perfectly squared boxes. Many models also automatically seal the bottom flaps, ensuring every carton is uniform, sturdy, and ready for packaging.

These machines are essential components of automated packaging lines and are widely used in high-volume environments.

A modern box erecting machine typically includes:

- Automatic carton magazine

- High-speed forming system

- Bottom flap folding mechanism

- Tape or hot-melt sealing module

- Height/width adjustment features

- Sensors and fault-detection systems

Brands like Soontrue (a global supplier of automation equipment) offer box erectors that integrate seamlessly with case packers, conveyors, sealing machines, and robotic palletizers, making them an ideal choice for businesses seeking automation upgrades.

Performance Comparison: Box Erector Machine vs Manual Case Forming

1. Productivity and Speed

Manual forming output: A trained worker can form approximately 2–4 boxes per minute (120–240 boxes/hour), and this number drops noticeably after hours of repetitive work.

Box erector machine output: A fully automatic box erector can form 10–40 boxes per minute, depending on the model. High-end machines can exceed 50 CPM.

Conclusion: A single box erecting machine can replace 3–8 workers, dramatically increasing throughput while maintaining consistency.

2. Labor Costs and Workforce Efficiency

Manual forming is labor-intensive, especially in peak seasons. You must hire, train, and retain workers capable of performing repetitive tasks. High turnover further increases labor costs.

In contrast, an automated box erecting machine:

- Reduces direct labor costs

- Minimizes overtime during peak periods

- Requires only minimal supervision

- Prevents labor shortages from slowing production

A company forming 2,000–4,000 boxes per day could save thousands of dollars per month by switching from manual forming to an automatic box erector.

3. Consistency and Accuracy

Manual forming often results in:

- Uneven box dimensions

- Skewed edges

- Loose or incomplete tape sealing

- Weak structural strength

A box erecting machine forms each box with identical precision. That consistency is vital for:

- Protecting delicate products

- Improving pallet stability

- Reducing box damage claims

- Maintaining a professional brand image

Consistency is also crucial for automated downstream equipment such as case packers or sealing machines, which require perfectly squared boxes to avoid jams.

4. Safety and Ergonomics

Manual box forming involves repetitive bending, folding, and taping motions. OSHA data shows that repetitive stress injuries are among the most common workplace injuries in packaging environments.

Using an automated box erector significantly improves workplace safety:

- Reduces repetitive strain

- Prevents cuts from cardboard and tape tools

- Eliminates fatigue-induced errors

- Requires minimal physical effort

With a safer environment, businesses experience fewer injuries and reduced workers' compensation costs.

5. Packaging Line Integration

Manual forming requires manual transport of cartons, breaking the flow of automated lines.

A box erecting machine—especially one designed by automation-focused manufacturers like Soontrue—can be seamlessly integrated with:

- Conveyor systems

- Case packers

- Shrink wrappers

- Weighing equipment

- Labelling systems

- Robotic palletizers

This creates a continuous, automated packaging process that eliminates bottlenecks and increases operational stability.

6. Material Waste Reduction

Manual forming often wastes materials through:

- Over-taping

- Incorrect folding

- Damaged cartons from poor handling

Automated box erecting machines apply the exact amount of tape or glue, ensuring perfect sealing while minimizing waste. Over time, these small savings accumulate and significantly reduce material expenses.

7. Machine Maintenance and Longevity

Some businesses delay automation because they fear maintenance costs. However, modern case erecting machines are built to operate reliably for years with only basic preventive maintenance:

- Periodic lubrication

- Tape or adhesive refill

- Occasional belt or blade replacement

Well-engineered machines—such as those offered by Soontrue—provide:

- Long operational lifespan

- Easy access components

- Diagnostic sensors

- User-friendly interfaces

- Strong after-sales support

This ensures long-term reliability and quick troubleshooting when needed.

Cost Comparison: Which Is More Cost-Effective?

Short-Term Perspective

Manual forming seems cheaper because it requires no initial investment. However:

- Labor cost grows every month

- Human errors cause expensive rework

- Slow forming limits productivity

Long-Term Perspective

A box erector machine pays for itself quickly by:

- Cutting labor costs

- Increasing output

- Reducing downtime

- Lowering material waste

Most companies recover the machine investment within 6–18 months, depending on production volume.

When Should You Choose Manual Case Forming?

Manual forming may still be ideal for:

- Very small businesses

- Low-volume packaging (under 200 boxes/day)

- Occasional carton forming

- Startups with minimal budget

- Projects with many box-size variations

For anything beyond that, automation becomes significantly more cost-effective.

When Is a Box Erector Machine the Better Choice?

A box erecting machine is the superior option if:

- Your daily carton volume exceeds 500 boxes

- You want consistent, professional-quality boxes

- Your facility suffers from labor shortages

- You aim to build a fully automated packaging line

- You need a scalable solution as your business grows

If you plan to integrate your packaging line with conveyors, robotic case packing, or palletizing, an automated box erector is essential.

Why Choose Soontrue as Your Box Erector Machine Supplier?

If your business is considering upgrading to automated box erecting equipment, Soontrue offers several advantages:

- High-speed, stable forming with advanced servo systems

- Multiple models for different box sizes and throughput requirements

- Durable mechanical design for long operating life

- Easy maintenance and user-friendly controls

- Flexible integration with sealing machines, packers, and palletizers

- Professional technical support

- Customization options for unique packaging needs

Soontrue focuses on building reliable, high-performance automation solutions that help businesses transition smoothly from manual forming to end-to-end packaging automation.

Conclusion

Both manual case forming and box erector machines have their place in the packaging world. For small businesses with low demand, manual forming may be sufficient. But for medium to large-scale operations—or any business prioritizing efficiency, consistency, and labor savings—an automated box erector machine is the clear winner.

By offering superior speed, precision, and integration potential, box erecting machines significantly strengthen packaging capacity and operational competitiveness. Brands like Soontrue further enhance this value by providing reliable, scalable systems designed for modern production environments.

Investing in a box erector machine is not just about automation—it's about future-proofing your entire packaging process.