Robotic Case Erector Machine

Application:

Mainly used for cartoning bakery food, snack food, frozen food, medicine, daily necessities and any other solid product automatically.

Introduction

Parameter

Robotic Case Erector Machine

Introduction:

Since 1993, Soontrue has become a domestic leader in the field of design and production of packaging machinery. With a team of over 100 engineers and technicians, strong R&D capabilities and rich industry experience, our product line has been expanding constantly. Our automatic cartoning machine can be very convenient to connect to the out-feed conveyor of the packaging machine and carton erecting machine. By the three-plus-one-axis manipulator, realizes movement and rotation in 3D space, quick-follow to conveyor belt, and precise pick-up & placement. Accurately and smoothly complete the action of product cartoning, that makes our automatic cartooning machine have a very wide range of applications in food, daily necessities, chemicals, and other industries.

Case Erector Machine Features

In addition, working with Soontrue’s horizontal packaging machine, vertical packing machine, pre-made bag packaging machine, box cartoning machine and other packaging machinery, it can effectively improve the automation of the entire production line and reduce labor costs.

Company advantages

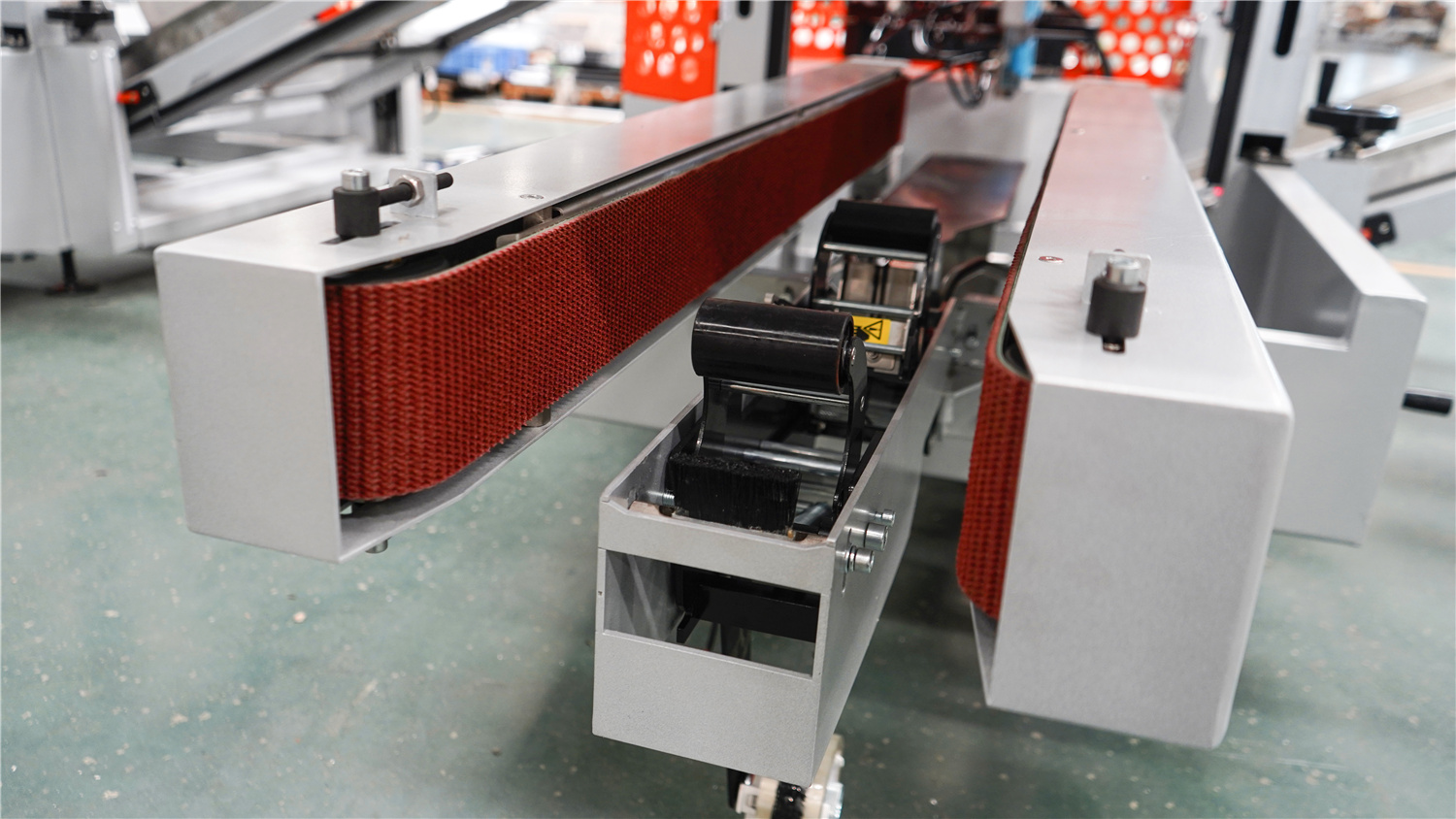

- Compact structure design with small foot print, easy to connect with production line.

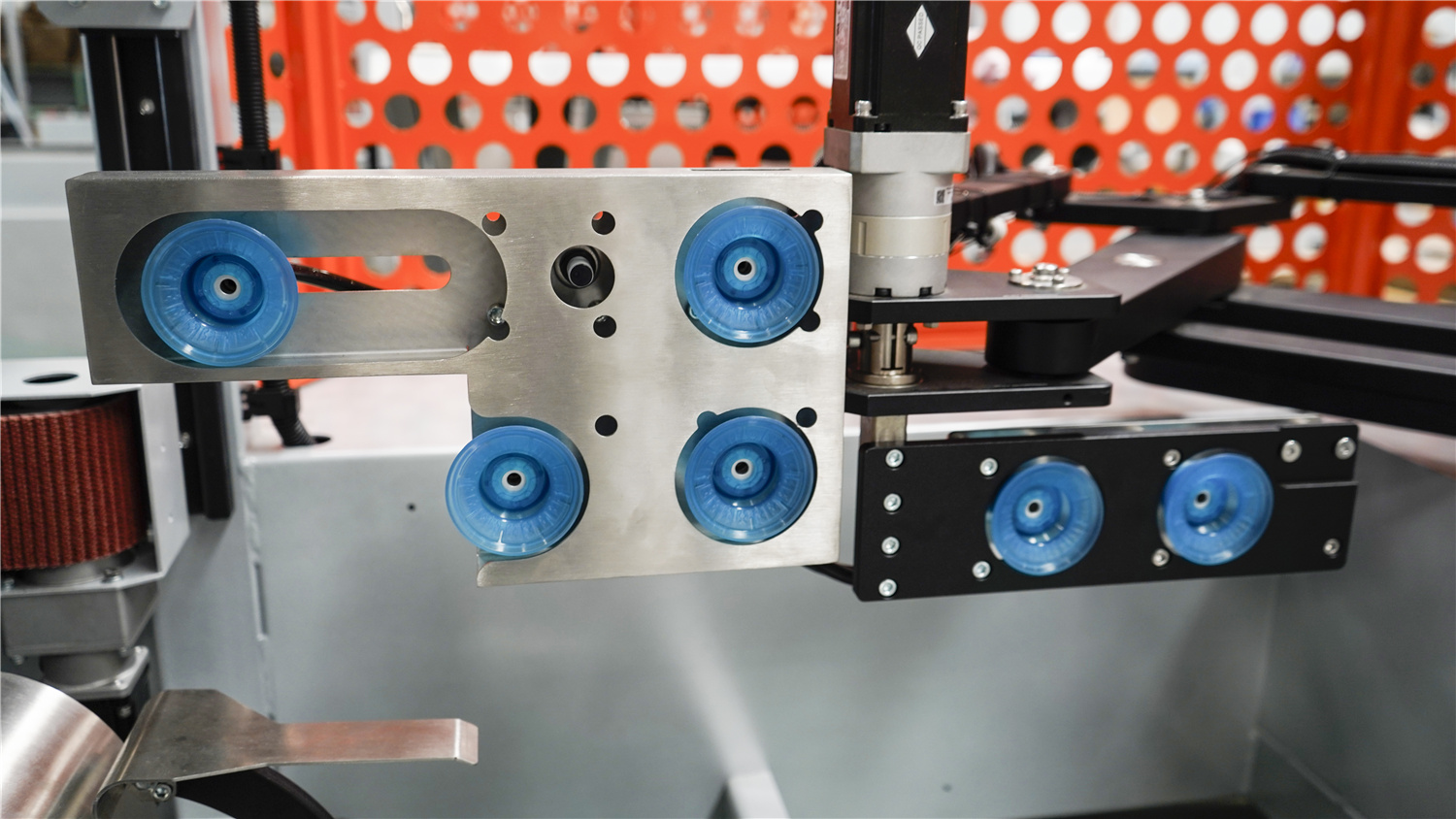

- Controlled by a motion controller, 4 servo-drive systems, with precise positioning and stable operation.

- Mechanical assembly with overload protection function, low energy consumption, safe and cost saving.

- Automatic alarm or shutdown function when product pick up failure happen.

- Robot arm motion, air suction, in-feed motion can be set via HMI, easy to operate

FAQ

Q1: Do products need to be placed on the conveyor belt by the same direction?

Answer: No need. The three-plus-one-axis manipulator can move and turn the product at the same time, automatically adjust the direction of the product, and accurately place it in the carton box.

Q2: I'm worried that I don't know how to operate your machine

Answer: Do not worry. Our cartoner is servo controlled, which greatly simplifies the difficulty of operation and commissioning. Most of the daily operation of the machine can be conducted by a few start-stop buttons and HMI. We can also provide instructional videos to give you step-by-step tutorial if necessary.

Q3: If I buy your carton packing machine, what technical support can I get?

Answer: We will provide you with 24-hour online technical support. In addition, we can also provide you with instructional videos on the installation and daily commissioning and maintenance. For some customized automatic packing line with carton box packing machine, our professional after-sales technicians can also provide on-site installation and commissioning services as per request (buyer should bear the cost for the service).

Q4: How do we build trust in the first business?

Answer: We believe that a win-win business must be based on our professional services and excellent products. Our team will fully study your needs, and clearly explain our products and solutions to you so that you can understand our services. We can take you to visit our modern factory through a video call, so that you can understand how your machine will be produced and let you know more about our products. Before delivery, we can cooperate with your partners to carry out factory acceptance test, or carry out acceptance through test video or video call. Make sure that the carton box machine you need is ready before shipment.

Q5: How can I find the suitable automatic box packing machine I need?

Answer: We will fully communicate of the information of your tissue, including the width and diameter of the jumbo roll, pattern type, paper thickness, grammage etc.

We have nearly 30 years of experience as a machinery manufacturer and can provide you with similar case videos for your reference. If necessary, we will ask you for samples of your tissue paper and packaging films for testing, in order to find the most suitable and cost-effective solution for you.

We have nearly 30 years of experience as a machinery manufacturer and can provide you with similar case videos for your reference. If necessary, we will ask you for samples of your tissue paper and packaging films for testing, in order to find the most suitable and cost-effective solution for you.

Technical Parameters:

| Model | TKXS-400 | TKXM-500 |

| Carton size range | L 142-420mm W 80-350mm H 150-350mm |

L280-500mm W150-400mm H150-400mm |

| Cartoning speed | 15-25 cases/min. | 15-25 cases/min |

| General power (KW) | 2.3KW | 3.0KW |

| Power supply type | 220V 1Ph 50Hz | |

| Machine weight | 550Kg | 620Kg |

| Machine dimensions | 2400×1900×1400 mm | 2600x2000x1450mm |

Related Products

Along with the market developing trends,Soontrue machines come into a servo age whom concentrated on researching and developing.