How Do Automated Packaging Systems Work?

In today's fast-paced industrial landscape, efficiency is paramount. Manufacturers are constantly seeking innovative solutions to streamline their production processes and meet the growing demands of consumers. Among these options, automated packaging systems stand out as a key component of contemporary production, providing exceptional speed, precision, and dependability. But how exactly do these sophisticated systems work?

Understanding Automated Packaging Systems

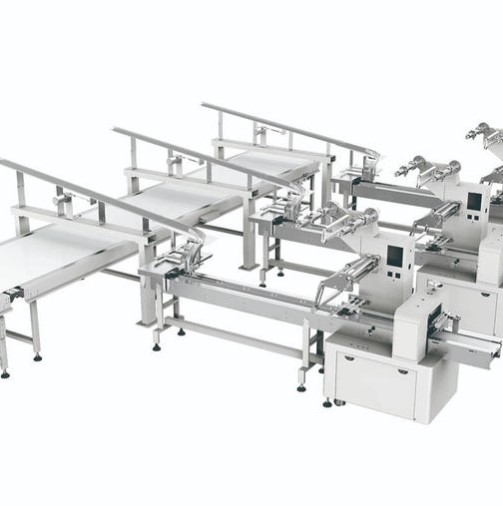

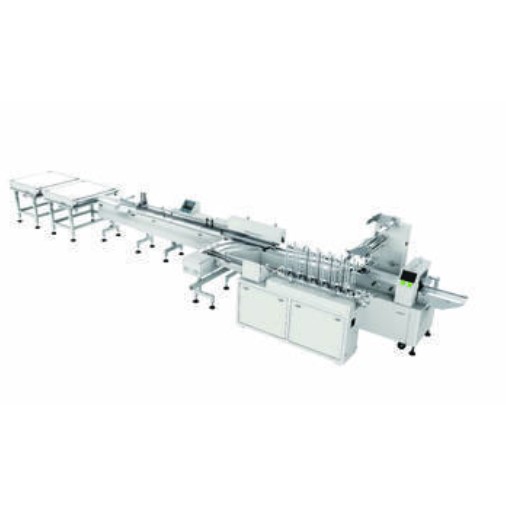

Automated packaging systems represent the convergence of cutting-edge technology and industrial automation.These systems are intended to automate the whole packaging process, from product sorting and arranging to sealing and labeling, with little human interaction. By leveraging robotics, sensors, and advanced software, they optimize efficiency, reduce labor costs, and ensure consistent product quality.

Key Components And Technologies

Robotic Arms:At the heart of automated packaging systems are robotic arms equipped with grippers or suction cups. These adaptable devices can pick up, move, and position objects with precise accuracy, even in high-speed conditions.

Conveyor Systems: Conveyor belts or rollers transport products through different stages of the packaging process. They maintain a smooth and continuous flow of commodities, boosting throughput while reducing downtime.

Vision Systems: Vision sensors and cameras play an important role in quality control and product identification. They inspect items for defects, verify packaging integrity, and guide robotic actions with real-time feedback.

Packaging Machinery: Automated systems integrate various packaging machinery such as form-fill-seal (FFS) machines, shrink wrappers, and case sealers. These devices accurately and efficiently handle specialized duties like as bagging, packaging, and sealing.

Control Software: Advanced software manages the whole packing process, synchronizing the movements of robots, conveyor belts, and machines. It optimizes workflow, adjusts parameters on the fly, and monitors performance to ensure smooth operation.

The Workflow of Automated Packaging Systems

Here is the workflow of automated packaging systems:

Product Feeding: Raw materials or completed goods are fed into the system, either manually or by automated conveyors, and then sorted and orientated for packing.

Product Inspection: Vision systems inspect each item for defects, size variations, or other quality issues. Faulty products are diverted for further inspection or rejection.

Packaging Selection: The system determines the proper packing materials, such as bags, cartons, or containers, based on the product characteristics and order requirements.

Packaging Process: The packing process is handled by robotic arms or specialized machines, which precisely and quickly fill containers, wrap items, and seal packages.

Labeling and Coding: Once packaged, products may undergo labeling and coding for traceability and compliance purposes. Automated systems apply labels, print batch codes, and inspect barcode readability.

Final Inspection and Sorting: Finished products undergo a final inspection to ensure they meet quality standards. They are sorted and routed for storage, shipping, or further processing.

Advantages of Automated Packaging Systems

Increased Efficiency and Productivity: Automated packaging systems operate with remarkable efficiency, often surpassing the capabilities of manual labor. By reducing human interaction and improving productivity, these systems can handle enormous numbers of items with constant speed and precision.

Enhanced Quality Control: Consistency is key in packaging operations, especially in industries where product integrity and safety are paramount. Automated packaging solutions excel at meeting stringent quality control standards by reducing the possibility of human mistakes.

Cost Savings: While the initial investment in automated packaging systems may seem substantial, the long-term cost savings they offer are significant. These technologies reduce labor expenses connected with packing processes by eliminating the need for manual labor.

Flexibility and Adaptability: Automated packaging systems offer unparalleled flexibility, allowing producers to rapidly adapt production processes to new goods, package types, or customization needs.

Improved Workplace Safety: Manual packing operations can endanger worker safety, including repetitive strain injuries, accidents when handling heavy goods, and exposure to dangerous chemicals. Automated packaging systems help mitigate these risks by minimizing the need for manual labor and reducing direct contact with potentially dangerous machinery or materials.

Conclusion

Automated packaging systems represent a paradigm shift in modern manufacturing, offering unparalleled efficiency, accuracy, and scalability.If you are looking for automated packaging machines, Soontrue is ideal for you. We specialize in offering various automated packaging machines. Choose our products and improve your business effectivity now!