Is an Automatic Packing System Right for Your Factory?

In today's increasingly competitive manufacturing landscape, factories must improve efficiency, reduce manual labor, and enhance packaging precision to stay ahead. One powerful way to achieve these goals is by integrating an automatic packing system—a suite of interconnected machines that streamline every aspect of product packaging.

But is this high-tech approach right for your production line?

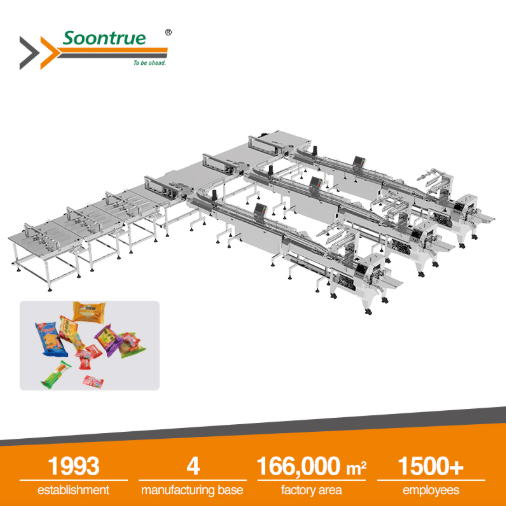

Let's explore how advanced automated packaging systems, particularly those offered by Soontrue, can transform your operations and bring measurable value to your factory.

What Makes Up an Automatic Packing System?

A modern automatic packing system is far more than just a packaging machine. It includes a wide range of modules and integrated solutions such as:

- Feeding Systems: Distributing feeding system, drop down feeding system, sinking feeding system, up and down feeding system, turn table feeding system, and side sorting feeding system.

- Stacking and Sorting: Automatic feeding and stacking system to ensure continuous product alignment and order.

- Wrapping and Sealing: Bagging & sealing machines like the SP300A, designed for high-speed, high-precision wrapping.

- Tray and Carton Automation: Automatic tray dispensers streamline packaging of products into trays before final boxing.

- Servo Control Systems: Precision-driven servo pushing systems for synchronized, efficient movement.

- Robotics: Collaborative robots assist in loading, unloading, or inspecting, working alongside human operators safely.

- Turnkey Solutions: Like the Automatic Wafer Packaging Line, integrating all modules into one cohesive line.

These components work in harmony to automate packaging processes from feeding to boxing, significantly improving speed, consistency, and safety.

Key Benefits of an Integrated Automatic Packing System

1. Seamless Product Feeding and Alignment

One of the most critical steps in packaging is product feeding. Soontrue's automated feeding systems—like the sinking feeding system and turn table feeding system—ensure that items are smoothly aligned for the next packaging stage, minimizing product jams or misfeeds.

2. Higher Throughput with Lower Labor Costs

Automation enables factories to handle larger volumes with minimal manual intervention. Systems like the distributing feeding system and servo pushing system allow for continuous packaging with consistent speeds, drastically reducing the need for labor-intensive tasks.

3. Flexible Integration with Collaborative Robots

Collaborative robots (cobots) are increasingly popular in packaging lines. These robots, like the ones from Soontrue, can be configured to pick, place, inspect, or load items with precision and safety, offering both flexibility and a small footprint.

4. Precision Sealing and Wrapping

The SP300A bagging and sealing machine from Soontrue is designed for high-speed production lines, capable of handling diverse film materials and product shapes. It ensures consistent sealing quality and protects the integrity of packaged items.

5. Scalable Solutions for Multiple Industries

Soontrue's automatic packing systems are suitable for a wide variety of sectors:

Food and snacks: like wafer biscuits, cakes, or noodles

Household goods: like tissues, soap, or cleaning sponges

Hardware and tools: screws, bolts, or packaged kits

Medical products: masks, gloves, or disposables

With modular setups, you can start with a basic system and scale up as needed.

Signs Your Factory Is Ready for an Automatic Packing System

Increasing Order Volume If your factory struggles to meet demand due to packaging delays, an automated solution can help maintain on-time delivery.

High Labor Costs or Shortages Packaging lines are labor-intensive. An automated tray dispenser, stacking system, or servo system reduces dependency on manual labor.

Inconsistent Packaging Quality Manual errors in sealing, sorting, or filling can damage your reputation. Soontrue's high-precision systems help ensure uniform packaging quality.

Frequent Product Changeovers Soontrue systems are designed for quick format switching, making them ideal for multi-product packaging lines.

Why Choose Soontrue?

Soontrue is a global leader in intelligent packaging solutions, offering a full suite of automatic packing systems that combine precision engineering, intuitive design, and industry-specific customization.

What Sets Soontrue Apart?

Comprehensive Product Portfolio: From collaborative robots to servo systems and complete packaging lines like the automatic wafer packaging line.

Industry Expertise: With decades of experience, Soontrue serves customers in food, hardware, daily chemicals, and more.

Customization: Whether you need a sinking feeding system or a side sorting feeding system, Soontrue tailors solutions to fit your exact needs.

Global Support Network: Soontrue provides worldwide installation, training, and technical support for uninterrupted operations.

Innovation: Soontrue integrates modern control systems, touchscreens, and IoT compatibility for smart factory automation.

How to Select the Right Configuration

When choosing an automatic packing system, consider the following:

Product Size & Shape: Choose feeding systems (e.g., turn table vs. drop down) based on item dimensions.

Packaging Format: Flow wraps, trays, cartons, or pillow packs? Each requires a different setup.

Speed Requirements: Identify your target output (e.g., units per minute) to determine machine capacity.

Floor Space: Modular systems like Soontrue's allow for flexible layouts to fit your available space.

Integration Goals: Do you need a complete line (feeding + bagging + boxing), or just a component upgrade?

A consultation with Soontrue's technical team can help assess your current production setup and recommend the ideal combination of machines.

Final Thoughts: Is an Automatic Packing System Right for You?

Investing in an automatic packing system isn't just about replacing workers with machines. It's about creating a smarter, faster, and more consistent production line—ready for the demands of tomorrow.

With solutions like:

- Servo pushing systems

- Collaborative robots

- Bagging and sealing machines

- Turn table and sinking feeding systems

- Automatic tray dispensers

- Complete wafer packaging lines

Soontrue empowers your factory to operate at peak performance, reduce human error, and respond flexibly to market needs.

Want to explore what Soontrue's automatic packaging systems can do for your factory? Reach out today and let our experts design the ideal solution for your business success.