What Is The Automated Packaging Process?

In the rapidly evolving landscape of modern manufacturing, efficiency and precision have become paramount. One crucial aspect that contributes significantly to achieving these goals is the automated packaging process. This revolutionary packing strategy not only increases production but also assures uniformity and precision in the end product. In this article, we will delve into the key components and benefits of the automated packaging process, shedding light on its importance in today's industrial landscape.

The Automated Packaging Process Defined

The automated packaging process entails the use of modern machinery and technology to accomplish different packaging operations without direct human participation. This process encompasses a range of activities, from filling and sealing to labeling and palletizing, all executed seamlessly by automated systems. The primary goal is to optimize the packaging line, reduce human error, and enhance overall operational efficiency.

Key Components Of Automated Packaging

Here are some key components of automated packaging:

Filling Systems

Filling systems that are automated properly measure and dispense the required quantity of product into packing containers. These systems can handle a wide range of product viscosities and consistencies, ensuring precise and consistent fills.

Sealing and Closing Machines

Sealing and closing machines utilize advanced technology to securely seal packages. Using heat sealing, glue sealing, or other methods, these devices ensure airtight and tamper-evident packaging.

Labeling Equipment

Automated labeling machines apply labels with speed and accuracy, ensuring that each product is properly identified. These systems can handle a variety of label kinds and sizes, resulting in a clean and professional appearance.

Palletizing Robots

In large-scale manufacturing facilities, palletizing robots take on the task of arranging finished products on pallets. These stacking robots improve the operation, assuring stability throughout transit and storage.

Quality Control Systems

Automated packaging lines often incorporate quality control systems, such as sensors and cameras, to inspect products for defects. This contributes to maintaining high standards and lowers the possibility of substandard packaging reaching customers.

Benefits of Automated Packaging

Increased Efficiency

Automation not only speeds up the packing process but also allows for continuous operation, decreasing downtime caused by manual labor. The result is higher production rates, increased throughput, and the ability to meet growing market demands effectively.

Consistency And Accuracy

Automated systems, by definition, do jobs with a degree of precision that is difficult to imitate manually. The consistency and accuracy offered by automation minimize variations in packaging quality, reducing the need for rework and ensuring that each product meets the established standards.

Cost Savings

While the initial investment in automated packaging equipment is high, the long-term advantages translate into significant cost reductions. Reduced labor costs, lower error rates, and increased overall efficiency contribute to a positive return on investment over time.

Adaptability And Scalability

The adaptability of automated packaging systems allows manufacturers to easily accommodate changes in product types, packaging formats, or production volumes. Because of its scalability, organizations can adapt swiftly to market swings and changing customer demands.

Conclusion

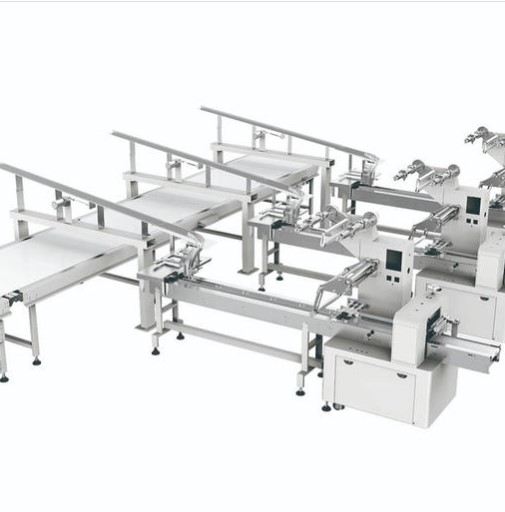

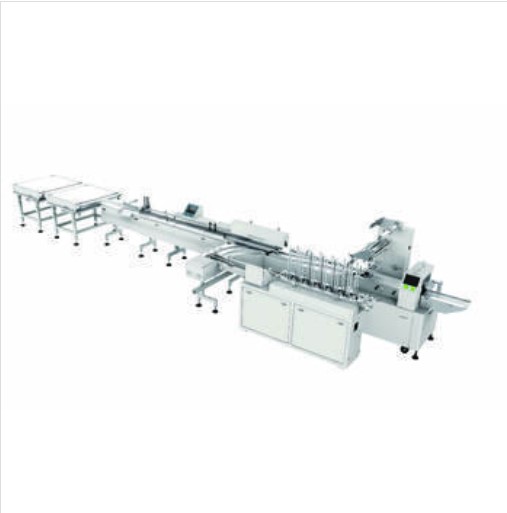

The automated packaging process stands as a testament to the continuous evolution of manufacturing practices. As a leading packing machine supplier, Soontrue is devoted to offering a wide range of packing machines including automatic packing machines, flow wrap packing machines, horizontal packing machines, etc. If you are interested in it, please feel free to browse our website for more product details!

FAQs

Q1: How does automated packaging improve efficiency in manufacturing?

A: Automated packaging improves efficiency in manufacturing by streamlining the entire packaging process. Filling, sealing, labeling, and palletizing tasks are performed with precision and speed, minimizing downtime and increasing overall production rates. The consistent and accurate execution of these tasks reduces the need for manual intervention, allowing manufacturers to meet growing demands efficiently.

Q2: What types of products are suitable for automated packaging?

A: Automated packaging is versatile and can be adapted to various product types across industries. It is suitable for a wide range of goods, including but not limited to liquids, powders, granular materials, and solid products. The flexibility of automated systems allows manufacturers to adjust parameters to accommodate different product viscosities, consistencies, and packaging formats.

Q3: How do automated packaging systems contribute to cost savings in the long run?

A: While the initial investment in automated packaging systems can be significant, the long-term benefits contribute to substantial cost savings. Automated processes reduce labor costs by minimizing the need for manual labor, and the decreased error rates result in less rework and waste. Additionally, the increased overall efficiency of the packaging line positively impacts the return on investment over time.