On edge packing machine - SI-150D

Application:

Mainly used for packing various regular and trayless product on edge. Such as biscuits, crackers, cookie, cake rust, dry bread, potato chips and so on.

Introduction

The SI-150D On-Edge Packing Machine is a horizontal flow wrap packaging solution designed for products that must be packed individually and on edge. It is especially suitable for regular, trayless products that require stable positioning, neat appearance, and high-speed packaging.

The SI-150D adopts a horizontal flow wrapping process, where products enter the machine horizontally and are wrapped with clear or printed film. The finished package features a tight fit, a horizontal back seal, and clean end seals, ensuring both protection and visual appeal.

Application

Mainly used for packing various regular and trayless products on edge, such as:

- Biscuits

- Crackers

- Cookies

- Cake rusks

- Dry bread

- Potato chips

- And similar products

Horizontal Flow Wrap Packaging Overview

Flow wrapping is a highly efficient horizontal packaging method widely used in food and consumer goods industries. The SI-150D is ideal for suppliers who require:

- Individual product packaging

- Stable product orientation

- Consistent sealing quality

- High production efficiency

With full servo control and intelligent HMI operation, the SI-150D delivers both flexibility and precision in daily production.

Horizontal Full Servo-Control Packaging Machine Features

Intelligent Servo System

- Simple system structure composed of servo motors, servo drivers, and touch screen

- Built-in motion control formula without independent controller

- Connector-based wiring for compact design and easy maintenance

- Competitive cost with stable performance

Easy Operation

- Intelligent HMI control system

- Simple parameter setting and quick adjustment

- Operator-friendly interface

Wide Bagging Size Range

- Bag length adjustable via color mark tracking or preset bag length

- Flexible setup for different product sizes

Shaftless Driving Technology

- No mechanical joints

- Each shaft driven independently by servo motor with gear reducer

- Higher accuracy and reduced mechanical wear

Auto-Shift Cutter

- Variable cutter shifting during operation

- Speed curve generated automatically

- No mechanical cam adjustment required

High-Speed Performance

- Maximum line speed up to 50 m/min

- Maximum packing speed up to 200 bags/min (double jaws)

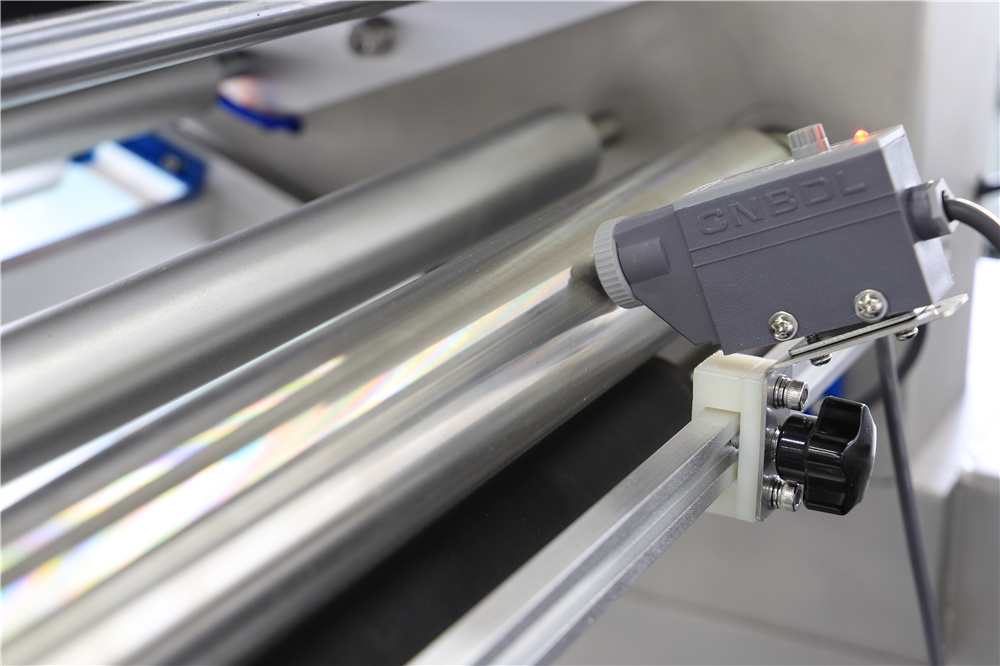

High Color Mark Tracking Accuracy

- Tracking accuracy up to 0.1 mm

Packless Function

- Ensures each package contains a product

- Eliminates empty bags

- Reduces film waste

Cutless Function

- Cutter stops automatically if product position is incorrect

- Machine restarts after product is discharged

- Prevents product damage

Automatic Film Splicer

- Splices new film roll automatically without stopping the machine

- Saves operation time and labor cost

Cutter Torque Protection

- Automatically detects cutter resistance

- Cutter stops and reverses when resistance exceeds preset value

- Torque value adjustable via touch screen

Customizable Special Functions

- Machine can be modified according to customer requirements

- Multiple safety protection devices

- Compatible with various automatic feeding systems

Machine Standard Features

- Sanitary machine design for easy cleaning

- Compact machine body with small footprint

- Intelligent control system with servo motors

- Color mark tracking

Easy integration with Soontrue's automatic feeding systems and upstream or downstream equipment

Maintenance and Inspection

Daily or Shift Maintenance

- Clean machine after each packaging run

- Turn off power and allow heating parts to cool before cleaning

- Do not spray water or steam directly on the machine

Main cleaning points:

- Remove material residue on in-feed conveyor using compressed air

- Clean cutter surface with wire brush and silicone oil

- Wipe control panel and safety covers with soft cloth

- Clean conductive ring of sealing tools weekly or bi-weekly

Monthly Maintenance

- Lubricate end sealer bearings

- Lubricate gears, chains, and pulleys

- Check and tighten chains and belts

- Inspect and tighten all fasteners

Semi-Annual Inspection

- Check and replace worn driving belts

- Inspect rubber rollers affecting film feeding

- Adjust brake unit of film-carrying roller

- Replace worn or damaged parts

- Check wiring terminals and clean electrical components with compressed air

FAQ

Q1: What types of food packaging machines do you have?

Answer: We recommend suitable models based on your product characteristics, size, and placement method, such as machines with top film loader, bottom film loader, rotary end sealing, or box motion end sealing. Different in-feed conveyors are also available, including chain type, belt type, and feeding-on-film type.

Q2: I'm worried that I don't know how to operate your machine.

Answer: Do not worry. Our packaging machines are fully servo controlled, which greatly simplifies operation and commissioning. Most daily operations are completed via start-stop buttons and HMI. Instructional videos are available, and the HMI memory function allows quick reload of saved parameters.

Q3: If I buy your automatic packaging machine, what technical support can I get?

Answer: We provide 24-hour online technical support for both customized packaging machines and automatic packaging systems. Installation, commissioning, and maintenance videos are available. On-site services can also be arranged for custom projects (buyer bears service costs).

Q4: How do we build trust in the first business?

Answer: We believe trust is built on professional service and excellent products. We can arrange factory tours via video call, conduct factory acceptance tests, or provide test videos before shipment to ensure the machine meets your expectations.

Q5: How can I find the custom packaging machine I need?

Answer: We will fully communicate your product information, packaging scheme, and feeding method. With nearly 30 years of experience as a packaging machine factory, we can provide similar case videos and conduct sample testing if required to identify the most suitable solution.

Flowpack Machine Manufacturer – Soontrue

Soontrue is a professional flowpack machine manufacturer with nearly three decades of experience in R&D, production, sales, and service. Equipped with advanced robot assembly lines, Soontrue can assemble a machine in as little as 30 minutes, ensuring stable quality and reliable delivery schedules.

With an annual output of up to 5,000 sets of packing machines, Soontrue provides customers worldwide with efficient, high-quality packaging solutions.

Stay competitive with Soontrue's Flowpack Machines—designed to enhance packaging efficiency, protect product quality, and elevate product presentation.

| Model | SI-150D |

| Bagging size range | L130-400mm W30-140mm H30-75mm |

| Packing speed | 30-110bags/min |

| Packing film width | 90-400mm |

| Packing material | OPP, OPP/CPP, PT/PE, KOP/CPP, PVDC/PVC etc. |

| General power | 9.3 kw |

| Power supply type | 1Ph. 220V 50Hz |

| Machine weight | 570Kg |

| Machine dimensions | 4200 x 969 x 1460mm |