XSJ10A Integrated dumpling machine

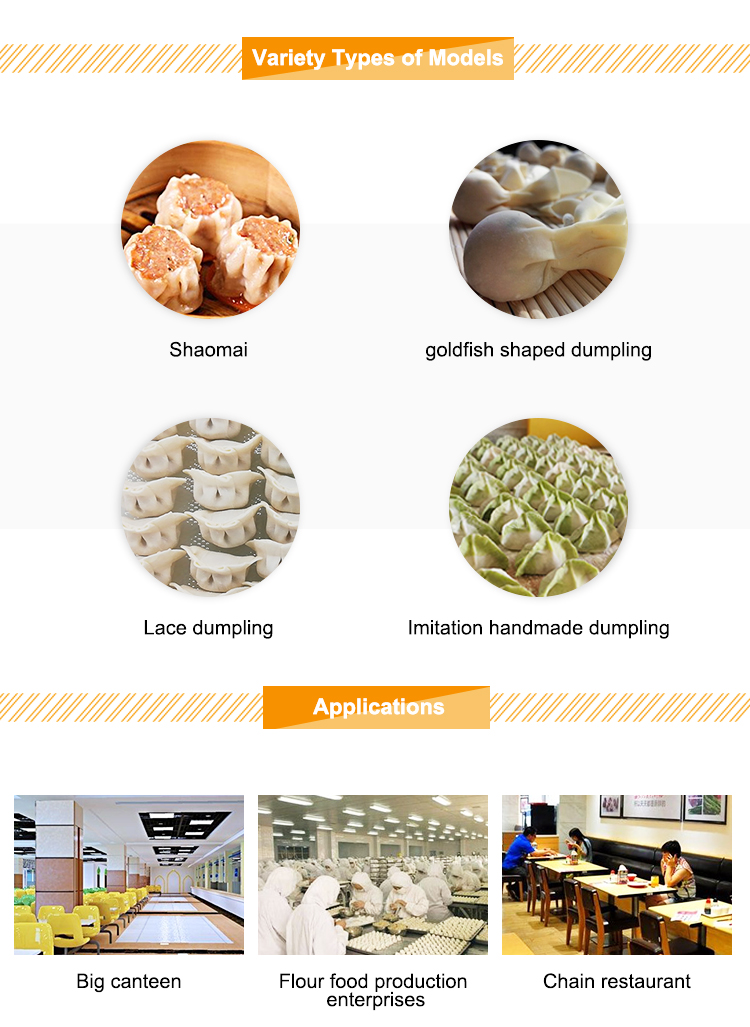

The XSJ10A Integrated Dumpling Machine is a versatile and efficient solution for dumpling production. It is specially designed for making lace dumplings or a wide variety of stuffed dumplings. Ideal for small to medium-scale food processing facilities, this machine integrates dough forming, stuffing, and shaping into a single compact unit, streamlining the dumpling production process and ensuring consistent quality.

Features:

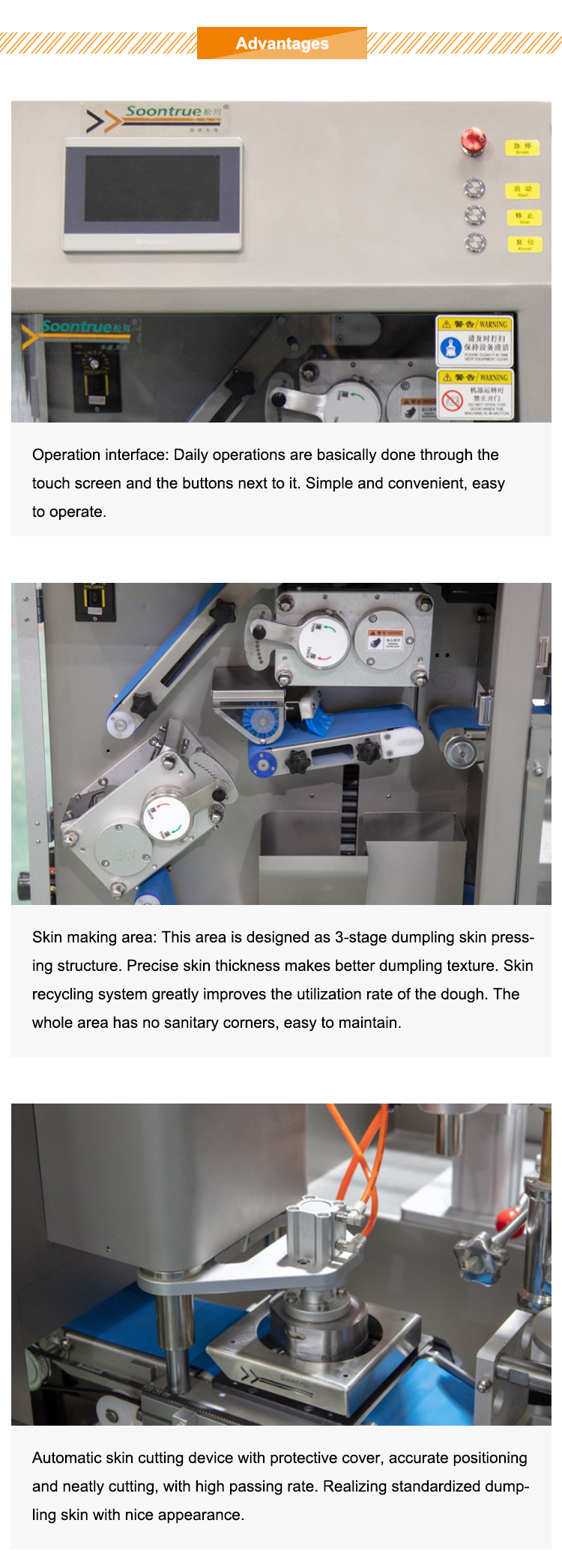

Easy operation: With humanity design, the entire machine just has 8 buttons. Easy to use the machine by new worker.

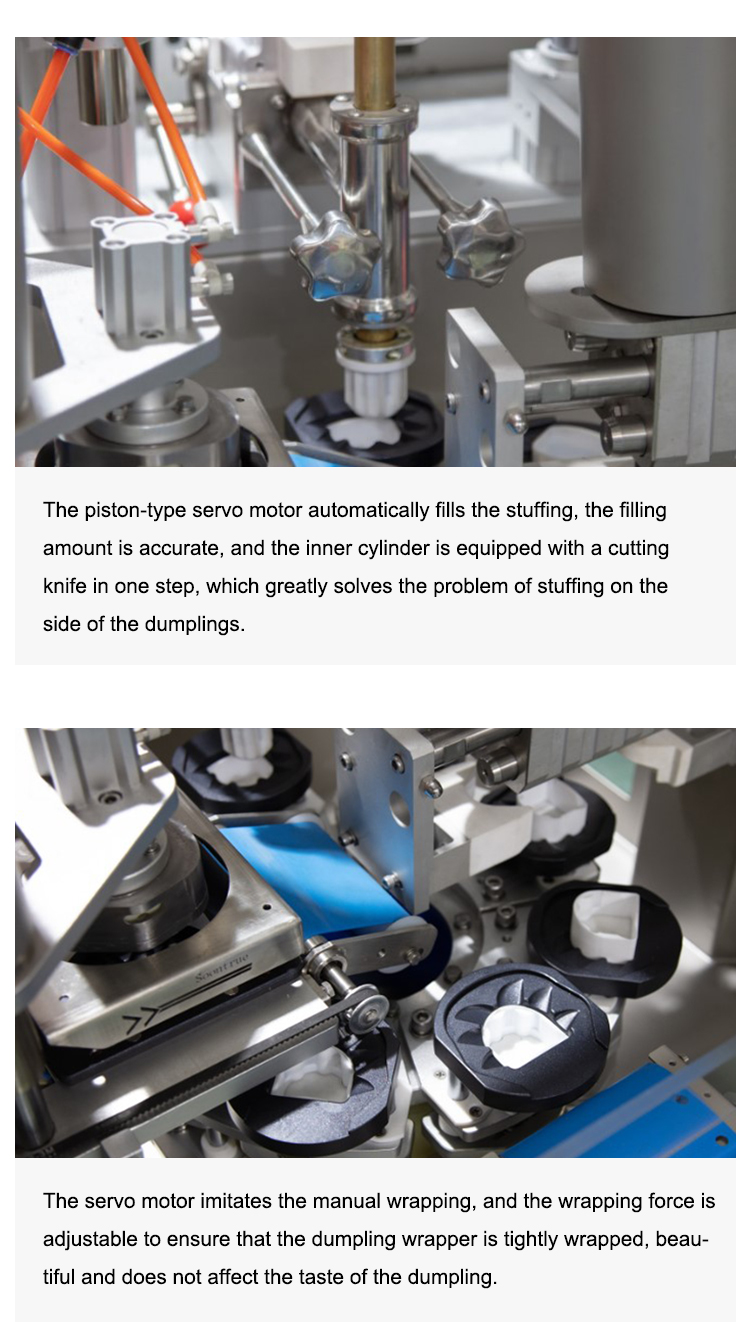

Easy cleaning: The dough rolling system for adopts cantilever design, there is no sanitary dead angle on machine. Tool-free design of filling system, easy to disassemble the regular parts for cleaning. It takes less than 30 min. to clean the whole machine. (The actual time depends on the worker’s proficiency.)

Economical and efficient: This machine adopts new patent for the dough rolling system with offcut returning device and dumpling forming system. Compared with the traditional dumpling machine, this integrated dumpling machine has lower requirements on the dough and stuffing, higher efficiency in the use of the dough and higher yield.

Certificate:

CE, ISO9001

Packing & Delivery:

Packing details: Packed in export standard wooden cases

Port of loading: Any port in China

Payment term:

T/T, LC etc.

FAQ

Q2:Does the dumpling wrapping machine have leftover dumpling skins recycle function?

Q3:Can a machine produce dumplings of different shapes by changing molds?

Q4:Is the dumpling making machine easy to operate?

Q5:Is the daily maintenance of the dumpling wrapping machine convenient?

Where to Find A Dumpling Packaging Machine Manufacturer?

What is A Dumpling Packing Machine?

Technical Parameters of Food Packing Machine:

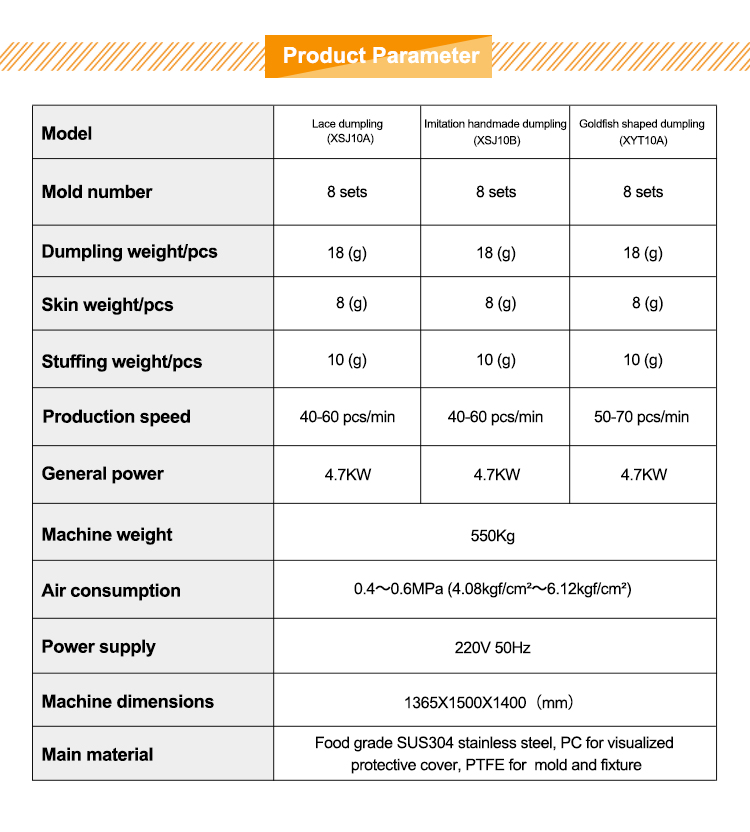

| Model | XSJ10A |

| Dumpling pattern | 18g Lace dumpling (Customizable) |

| Forming type | Imitated hand-made,Wrapping type |

| Forming molds numbers | 8 group |

| Capacity | 40-60 pcs/min.(Depends on product process) |

| General power | 4.7 kw |

| Power supply type | 1Ph. 220V 50Hz |

| Machine weight | 550Kg |

| Machine dimensions | 1365 x 1500 x 1400mm |