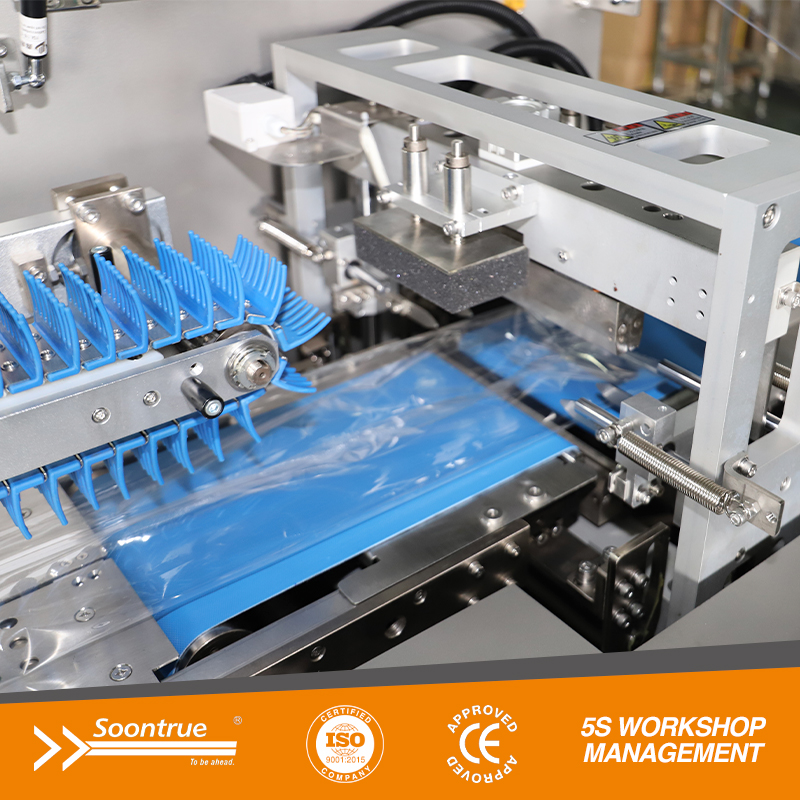

SW80E Box Motion Flow packaging Machine

Application:

Mainly used for packing various regular and solid products such as cake, bread, biscuit, instant noodles, candy, chocolate, daily necessities, face mask, chemical product, medicine, hardware or any product in tray.

SW80E Box Motion Flow Wrapping Machine

Introduction to Box Motion Flow Wrapping Machine:

SW80E horizontal flow wrap machine is ideal for suppliers of products that must be packaged individually. Flow wrapping is a horizontal packaging process in which product enters the machinery and is wrapped in clear or printed film. The result is a tightly fitted flexible package with a horizontal back seal and end seal.

Application:

Suitable for packing soft, sticky or multi pack products such as towel, tissue, noodles, egg rolls, sausages, ice lolly, ice cream bar, soft candy, cutlery, vegetables, etc.

Packing Exambers:

The SW80E Box Motion Flow Packaging Machine is a fully servo-controlled horizontal flow wrapper designed for high precision, efficiency, and flexibility. With advanced automation features, wide bagging size range, and customizable functions, it is ideal for diverse industries requiring stable, fast, and hygienic packaging solutions.

Our experienced R&D engineers can provide customized packaging solutions tailored to your product characteristics.

Key Features

Full Servo-Control System

Simplified structure with servo motors, drivers, and HMI.

Compact design, easy maintenance, and cost-effective.

User-Friendly Operation

Intelligent HMI for easy parameter settings and quick adjustments.

Flexible Bag Size

Wide bag length range, adjustable via color mark tracking or preset values.

Advanced Motion Control

Shaftless driving system with each axis controlled by a servo motor.

Auto-shift cutter with automatic speed curve generation.

High Speed & Accuracy

Up to 200 bags/min (double jaws).

Line speed up to 50m/min.

Color mark tracking accuracy up to 0.1mm.

Smart Functions

Packless function: No empty bags, reduced film waste.

Cutless function: Protects products if out of position.

Film splicer: Automatic film roll splicing without stopping.

Torque protection: Prevents cutter damage from hard products.

Customizable Options

Can be integrated with automatic feeding systems.

Additional safety protection devices available.

Standard Features

Sanitary design for easy cleaning.

Compact structure with a smaller footprint.

Intelligent servo-driven control system.

High-precision color mark tracking.

Seamless integration with Soontrue's upstream & downstream equipment.

Maintenance & Inspection

Daily / Shift Maintenance

Clean conveyors, cutter surface, control panel, and sealing tools.

Always power off before cleaning.

Avoid spraying water/steam directly on the machine.

Monthly Maintenance

Lubricate bearings, gears, and chains.

Check chain/belt tightness and fasten loose screws/nuts.

Half-Yearly Inspection

Replace worn belts or rollers.

Adjust brake units.

Inspect electrical components, clean with compressed air.

FAQ – Box Motion Flow Wrapping Machine

Q1: What types of food packaging machines do you provide?

A: We recommend models based on product type and feeding method, such as top/bottom film loaders, rotary end sealing, box motion sealing, and chain/belt conveyors.

Q2: I'm worried I don't know how to operate the machine.

A: Our packaging machine uses servo control HMI, making operation simple. We provide instructional videos and the HMI supports memory function for fast recall.

Q3: What technical support is available after purchase?

A: We provide 24/7 online technical support, videos for installation and maintenance, and on-site commissioning for large projects (buyer covers costs).

Q4: How do we build trust in the first cooperation?

A: We ensure transparency via video factory tours, acceptance tests before shipment, and sharing case references to prove machine quality.

Q5: How can I find the right custom packaging machine?

A: Share your product samples, packaging films, and feeding requirements. With 30 years of experience, we will design the most cost-effective and reliable solution for you.

Why Choose Soontrue?

Founded in 1993, Soontrue is one of China's most reliable flow wrapping machine manufacturers. With excellent machines, professional service, and strong global reputation, we provide innovative and dependable packaging solutions trusted by clients worldwide.

The SW80E Box Motion Flow Packaging Machine is the ultimate choice for businesses seeking high-speed, precise, and customizable flow wrapping solutions with long-term reliability.

Technical Parameters:

| Model | SW60E | SW60X | SW80E | SW80X |

| Product size L | 90-450mm | 90-420mm | L90-450mm | L90-450mm |

| Product size W | 10-180mm | 10-180mm | W35-200mm | W35-200mm |

| Product size H | 5-60mm | 5-60mm | H5-80mm | H5-80mm |

| Packing speed | 30-120 bags/min. | 30-120 bags/min. | 30-100 bags/min. | 30-100 bags/min. |

| Packing film width | 90-420mm | 90-420mm | 90-500mm | 90-500mm |

| Packing material | OPP, OPP/CPP, PT/PE, KOP/CPP, PVDC/PVC etc. | |||

| General power | 7.5 kw | 8.0 kw | 8 kw | 8 kw |

| Power supply type | 1Ph. 220V 50Hz | |||

| Machine weight | 700Kg | 730Kg | 700Kg | 700Kg |

| Machine dimensions | 4140x870x1630mm | 4820x1065x1450mm | 4360 x 1020 x 1540mm | 5100x1100x1500mm |