Pre-Made Bag Packing Machine with Multi-Head Weigher

Application:

This multihead weigher packing machine is suitable for automatic packaging of granular strip, sheet, block, ball shape, powder and other products. Such as snack, chips, popcorn, puffed food,dried fruits, cookies, biscuits, candies, nuts, rice,beans, grains, sugar, salt, pet food, pasta, sunflower seeds, gummy candies, lollipop, Sesame.

Application:

All kinds of grains and solids material, like candy, nuts, raisins, peanuts, melon seeds, nuts,nutlet, chocolate, preserved fruit,potato chips,biscuits,confect, camphorball, currant, almond,potato crisps, pet food, dilatant food etc can be weighed by the ration. It is also suitable for weighing small hardware and plastic component.

Suitable Pouch: all type of heat sealable performed side seal bags, block bottom, bags, zip-lock recloseable bags, stand-up pouch with or without spout, paper bags, flat pouch, stand-up pouch, zipper pouch, spout pouch, m gusset pouch, paper pouch, aluminium foil pouch, etc.

Packing Exambers:

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Multihead Weigher Doypack Packing Machine: Features

●Wide application : various shapes, state and nature of products (such as candy, chips, nuts, frozen dumplings, biscuits,mothballs, pet food, puffed food, hardware, plastic parts, etc.)

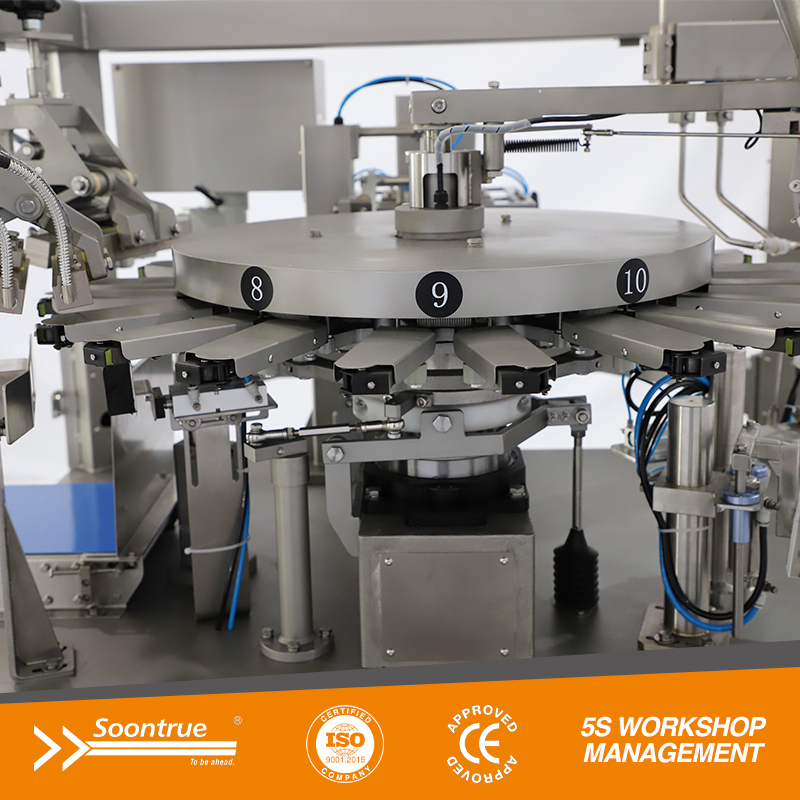

●8-10-station structure, controlled by an IPC and HMI for centralized control, making it easy and convenient to operate.

●Equipped with an automatic fault tracking and alarm system, displaying real-time operation status.

●Includes a bag tracking detection device, preventing sealing when there is no bag opening or no material, thus saving packaging materials.

●Utilizes a fully servo-controlled system for fast and accurate execution of motions.

●The overall machine design complies with GMP standards and is CE certified.

System Unite

1: Z shape bucket elevator conveyor

2: 10/14 head multihead weigher

3: Working Platform

4: Premade Bag Packing Machine/Doypack Pouch Packing Machine

Multihead Weigher Doypack Packing Machine: optional accessories

multi-head weigher

1. One of the most economic&stable multi-head weigher in the world the best cost-effective

2. Stagger Dump avoid bigger items pile up

3. Individual feeder control

4. User friendly touch screen equipped with multiple language

5. Compatible with single packaging machine, rotary bagger, cup/bottle machine, tray sealer etc.

6. 99 preset program for multiple tasks.

SUPPORTING PLATFORM

The supporting platform is solid will not affect the measurement accuracy of the combination weigher.

In addition, the table board is to use the dimple plate, it is more secure, and it can avoid slipping.

● Specification

The size of the supporting platform is according to the type of the machines.

Z-TYPE CONVEYOR

The conveyor is applicable for vertical lifting of grain material in departments such as corn, food, fodder and chemical industry, etc. For the lifting machine,

the hopper is driven by the chains to lift. It’s used for vertical feeding of grain or small block material. It has advantages of large lifting quantity and highness.

OUTPUT CONVEYOR

The machine can send the packed finished bag to after-package detecting device or packing platform.

Pre-Made Bag Packing Machine with Multi-Head Weigher

Product Overview

The Pre-Made Bag Packing Machine with Multi-Head Weigher is designed for granular, block, and irregular food products, providing high weighing accuracy, consistent packaging quality, and fully automated performance. Paired with a premium multi-head weigher, this system improves efficiency while reducing labor intensity and product waste — ideal for snacks, nuts, frozen foods, pet food, confectionery, and more.

Soontrue delivers tailored pouch packaging solutions with flexible configurations to meet diverse production needs.

Why Choose Soontrue Multi-Head Weigher Premade Bag Packing System?

- High weighing accuracy with advanced combination algorithm

- Servo-controlled system for stable and flexible operation

- Durable and hygienic construction for food industry compliance

- Supports multiple pouch formats — stand-up pouches, zipper bags, flat pouches, etc.

- Intelligent empty bag detection and fault alarm → reduce material waste

- Capable of continuous, high-speed packaging

- Supports easy cleaning and quick changeover for different products

Nearly 30 years of automation expertise ensures industry-leading reliability and efficiency.

How Does the Multi-Head Weighing System Work?

The packaging workflow includes 5 precise steps:

Filling – Product is distributed into multiple individual hoppers

Weighing – Load cells measure each hopper independently

Combination Calculation – Algorithm selects the best weight match to meet target weight

Discharge – Selected hoppers release products into the funnel

Bag Filling & Sealing – Accurate dosing into premade bags, then sealing and output

Accurate | Fast | Low waste — ideal for light or fragile materials’ packaging.

Trusted Manufacturer – Soontrue

Founded in 1993, Soontrue is a professional premade pouch packing machine & multi-head weigher system manufacturer, integrating:

- R&D

- Production

- Sales

- After-sales service

Our servo motor-driven equipment represents the latest innovation in packaging machinery, ensuring high accuracy, lower downtime, and long-term operational savings. We support customers with custom automation solutions for upgrading production lines worldwide.

FAQ – Multi-Head Weigher Packing Machine

Q1: How do I select the right premade bag packing machine?

We will propose configurations based on your product size, flow characteristics, bag type, and feeding method. Suitable for pillow bags, flat bags, doypack, zipper bags, etc.

Q2: Is the machine difficult to operate?

No. Servo-control HMI makes operation intuitive. We provide training videos and remote guidance. HMI supports parameter memory for quick product changeovers.

Q3: What technical support will I get?

24/7 online service, installation/commissioning videos. For customized large-scale systems, we offer on-site service upon request (buyer covers related cost).

Q4: How do you ensure trust in the first cooperation?

Video factory tours, acceptance test reports or livestream FAT, and transparent communication ensure the machine fully meets requirements before shipment.

Q5: How can I confirm the right custom solution?

We analyze product information, packaging goals, and automation plans. Sample testing is available for optimal and cost-effective system configuration.

Applications

- Snacks & candies

- Frozen dumplings / meatballs

- Nuts & grains

- Pet food / seafood

- Hardware parts & non-food granules

Doypack Packaging Machine: Technical Parameters

| Model | GDS180-06 | GDS210-08 | GDS210-10 | GDS260-08 | GDS300-08 |

| Bagging size range | L≤360mm W70-180mm |

L120-380mm W80-210mm |

L120-380mm W80-210mm |

L≤400mm W130-260mm |

L≤400mm W160-300mm |

| Packing speed | ≤60 pouches/min. | ≤70 pouches/min. | ≤100 pouches/min. | ≤72 pouches/min. | ≤65 pouches/min. |

| Packing type | Premade bag (flat bag, doypack, zipper bag, hand bag, M bag and other irregular bag) | ||||

| Air consumption | 6kg/cm² 80L/min. | ||||

| Power supply type | 3Ph. 380V 50Hz | ||||

| Machine weight | 400Kg | 500Kg | 600Kg | 580kg | 650Kg |

| Machine dimensions | 1500x1400x1520mm | 1700x1140x1470mm | 1900x1340x1520mm | 1850x1250x1520mm | 2100x1500x1520mm |