XSM10A Siumai siomai Machine (Shaomai)

Application:

Used for making Siumai siomai (Shaomai)

Features:

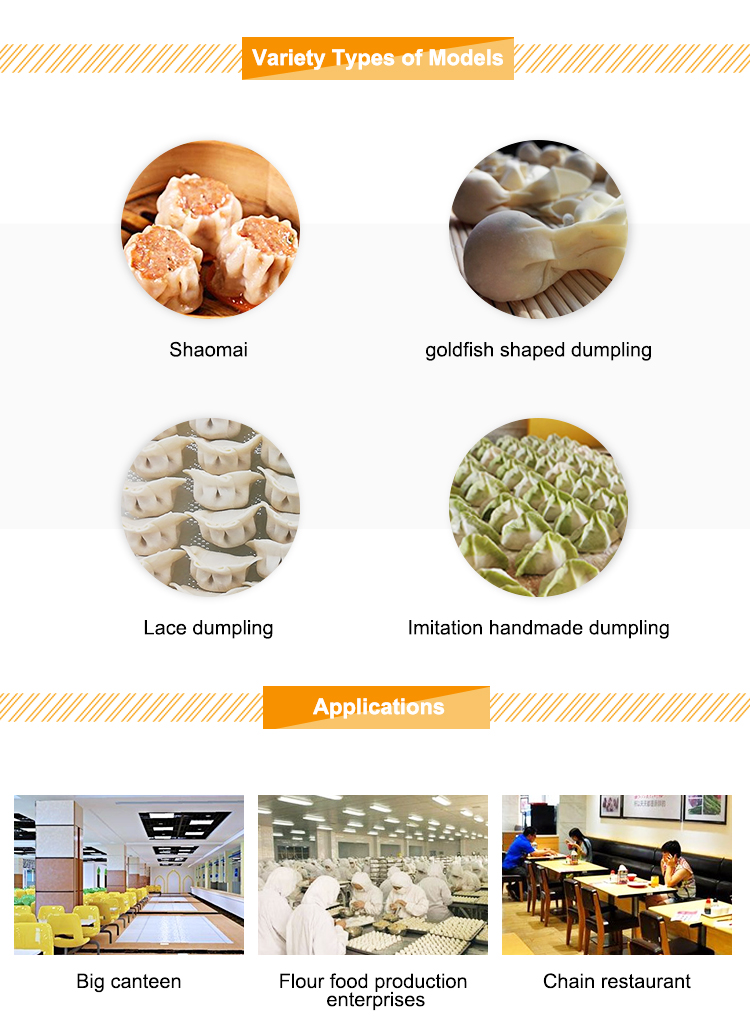

The dumpling making machine is a machine that can automatically make dumplings. With pre-made dough and stuffing, the automatic dumpling machine can complete the processes of skin pressing & making, stuffing filling, and dumpling forming. This product can greatly improve the stability of product quality, reduce labor costs, and is widely used in large canteens, frozen dumpling production enterprises and chain restaurants. The dumpling machine can make dumplings of various shapes, such as lace dumplings, hand-made dumplings, goldfish wontons, siu mai, etc. In the future, more dumpling shapes will be developed to meet the needs of different markets.

Certificate:

CE, ISO9001

Packing & Delivery:

Packing details: Packed in export standard wooden cases

Port of loading: Any port in China

Payment term:

T/T, LC etc.

| Model | XSM10A |

| Dumpling pattern | 23g、25g Siomai |

| Forming type | Wrapping type |

| Forming molds numbers | 8 group |

| Capacity | 40-60 pcs/min.(Depends on product process) |

| General power | 4.7 kw |

| Power supply type | 1Ph. 220V 50Hz |

| Machine weight | 550Kg |

| Machine dimensions | 1365 x 1500 x 1400mm |

Introduction

The Box Motion Flow Wrapping Machine - SW60E is a horizontal full servo-control packaging machine designed for packing irregular or sticky products, such as vegetables, egg rolls, sausages, ice lollies, bread, chocolate blocks, noodles, pizza, hardware, and more.

With a compact design, intelligent control system, and versatile features, the SW60E ensures high-speed, accurate, and consistent packaging, making it ideal for manufacturers looking for a reliable box packaging machine.

Application

This machine is suitable for packing various types of products that are irregular in shape or sticky, including:

- Food products: vegetables, sausages, bread, ice lollies, chocolate blocks, noodles, pizza, egg rolls

- Non-food items: hardware or industrial products

- Any product requiring precise horizontal flow wrapping

The machine can be integrated into complete production lines with automatic feeding systems and other upstream or downstream packaging equipment.

Horizontal Full Servo-Control Packaging Machine Features

Simple System Structure: Built with servo motors, servo driver, and touch screen. The servo driver contains the motion control formula, eliminating the need for independent controllers. All wiring is connector assembly.

Easy Operation: Intelligent HMI control allows simple parameter settings and adjustments.

Big Bagging Size Range: Bag length can be set via color mark tracking or preset length.

Shaftless Driving: Each shaft controlled by a servo motor with gear reducer; no mechanical joints.

Auto-Shift Cutter: Variable speed curve for automatic cutting without manual adjustment.

High Speed & Accuracy: Max line speed up to 50m/min, packing speed up to 200 bags/min (double jaws), color mark tracking accuracy 0.1mm.

Packless & Cutless Functions: Avoid empty bags and prevent misaligned product cutting.

Film Splicer: Automatically splices new film rolls without stopping the machine.

Cutter Torque Protection: Protects machine from hard product stress; adjustable via touch screen.

Customizable Functions: Machine can be modified per customer requirements.

Safety & Sanitation: Multiple safety protection devices; sanitary design for easy cleaning.

SW60E Box Packer Machine Standard Features

- Compact body, smaller footprint

- Intelligent control system with servo motors

- Easy integration with Soontrue's automatic feeding systems

- High-speed box packaging with precision control

- Color mark tracking

Maintenance and Inspection

Daily / Shift Maintenance:

- Clean machine after each packaging session

- Turn off power before cleaning hot parts

- Remove debris from in-feed conveyor and cutter surface

- Clean control panel, safety cover, and operating surface

- Clean conductive ring of sealing tools weekly

Monthly Maintenance:

- Apply lubricating grease to bearings, gears, and chains

- Check and tighten chains, belts, screws, and nuts

Biannual Inspection:

- Inspect wear on belts and rubber rollers; replace if necessary

- Adjust brake unit of film-carrying roller

- Inspect all wear parts and electrical wiring; clean inverter and control boards

FAQ

Q1: What type of machine for food packaging do you have?

Answer: We provide models with top film loader, bottom film loader, rotary end sealing, box motion end sealing, and various in-feed conveyor types (chain, belt, feeding-on-film), suitable for different product feeding methods.

Q2: I'm worried that I don't know how to operate your machine.

Answer: No need to worry. The machine is servo-controlled, simplifying operation. Daily tasks can be managed via start-stop buttons and HMI. Instructional videos are available for changing products or packaging styles.

Q3: If I buy your automatic packaging machine, what technical support can I get?

Answer: We provide 24-hour online technical support, instructional videos, and on-site commissioning services for custom-made automatic packing systems.

Q4: How do we build trust in the first business?

Answer: We offer professional service, clear product explanations, factory video tours, and support factory acceptance tests or video inspections before shipment.

Q5: How can I find the custom packaging machine I need?

Answer: We communicate details of your products, packaging scheme, and feeding methods. Testing with product samples and packaging films ensures the most suitable and cost-effective solution.

Additional Information

Types of Boxes Sealed: Can pack all common box types. Contact us for models suitable for irregular-shaped products.

Operation Staff: Typically 1-2 operators are enough; once set up, the machine can complete packaging automatically.

Packing Speed: With 6 servo control system, speeds range from 30–120 bpm. Theoretically, there is no limitation on the number of boxes processed.

| Model | XSM10A |

| Dumpling pattern | 23g、25g Siomai |

| Forming type | Wrapping type |

| Forming molds numbers | 8 group |

| Capacity | 40-60 pcs/min.(Depends on product process) |

| General power | 4.7 kw |

| Power supply type | 1Ph. 220V 50Hz |

| Machine weight | 550Kg |

| Machine dimensions | 1365 x 1500 x 1400mm |